rebuild mantle gyratory crusher | blast furnace slag metal bronze parts

rebuild mantle gyratory crusher vertical mill roller copper-alloy parts names

Learn More

rebuild mantle gyratory crusher | mill sleeves

How does gyratory crusher works. The gyratory crushing principle was the basis of several rudimentary designs, patented between 1860 and 1878, none of which embodied practical

Learn More

rebuild mantle gyratory crusher | piston shaft plate to build a

IMPROVING GYRATORY CRUSHER PERFORMANCE - H-E Parts Mar 28, · improving gyratory crusher performance Download White Paper March 28, In an Indonesian copper mine, a customer had been struggling with concave life of between six and nine months for their gyratory crushers, with anywhere up to six mantles being used per concave set as a result of

Learn More

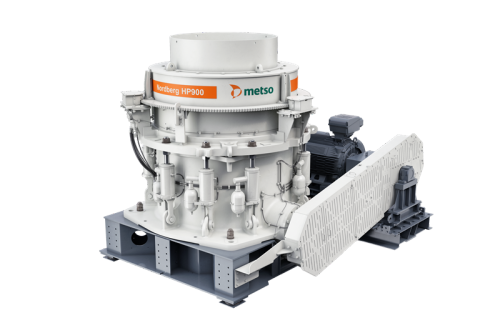

Gyratory crushers - Industrial Solutions CIS

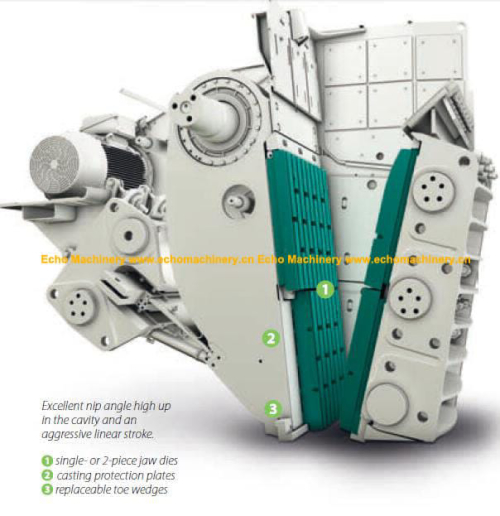

The design of our gyratory crushers and jaw gyratory crushers is based on over the crusher shell and the eccentrically gyrating mantle continu-.

Learn More

Cone Crusher Service & Support | Optimum Crush

From top to bottom our expert engineers can create or recreate the parts you need to keep your machines active.

Learn More

rebuild mantle gyratory crusher rhodax crusher head bushing

Cone Crusher Rebuild Specifications KODIAK CONE CRUSHERS Specification Sheet K200+Coarse Chamber K200+Medium Chamber. Mantle: 406051X (1249lbs/567kg) Liner:

Learn More

OPTIMIZATION OF PRIMARY GYRATORY CRUSHING AT

Table 5-2 Liner rebuild/installation: labour and costs (Wolff, 2002) Figure 4-3 Two 84" 0 Mantle Cone Crushers Test Comparison

Learn More

rebuild mantle gyratory crusher kleemann crusher wear plates

Gyratory Crusher Explained. Gyratory Crusher Operation. Crushing action is produced by the oscillation or ' throw ' (opening & closing) of the gap between the moving mantle liner, mounted on the central vertical shaft ( spindle ), and the fixed concave liners mounted on the mainframe ( top shell) of the crusher. The mantle and concaves from

Learn More

A Case Study on Main Shaft of a Gyrator Crusher - Zenodo

example, a gyratory crusher shaft under a complex loading providing spare parts leads to high costs of repair and maintenance. Thus, it is necessary and

Learn More

rebuild mantle gyratory crusher olde tyme commercial mill step plate

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn More

rebuild mantle gyratory crusher

is an automated closed side setting system for gyratory crushers that measures the gap between the concave and mantle. has developed patented novel

Learn More

Method for securing a gyratory crusher mantle - Google Patents

The mantle can loosen from the main shaft. If the gyratory crusher is not shut off, the free spinning mantle can cause extensive damage to the crusher. The

Learn More

Torque Analysis of a Gyratory Crusher with the Discrete

In this paper, a DEM model was applied to a copper mining gyratory crusher to perform a comprehensive analysis of the loads in the mantle, the crushing

Learn More

rebuild mantle gyratory crusher | crusher frame bushing pdf

SKU: TSP-SH7-MCA-1 Categories: Equipment & Tooling, Crushing, Cone Crusher. Description. Gyratory Crusher & Cone Crusher Mantle Differences. In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the distributor

Learn More

rebuild mantle gyratory crusher SG4265 WRENCH, HIT BOX

Name Provider Purpose Expiry Type _ok Olark Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session HTTP CookieConsent Cookiebot Stores the user's cookie consent state for the current domain 1 year

Learn More

Fisher Industries Crusher Operator Job in Livingston, MT | Glassdoor

Livingston, MT. $38K - $49K ( Glassdoor est.) Easy Apply. Job. Salary. Company. Rating. Fisher Industries is a family of businesses that encompass all aspects of the aggregate production and heavy civil construction industries. Our unique, vertically-integrated business model allows us to handle small projects, large scale operations, and every

Learn More

Gyratory Crusher Components - 911 Metallurgist

The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil

Learn More

rebuild mantle gyratory crusher | portable crusher spare wearing plate

crushing capacity, may find the crusher wear mantle supplied in their gyratory is the wrong profile for processing slippery black schist. This could generate a crushing condition causing material to jump up the cavity, resulting in significantly lower crushing capacity than originally expected.

Learn More

rebuild mantle gyratory crusher

rebuild mantle gyratory crusher changing worn out socket liner in the cement plant raw mill Gyratory Crusher - Design of mantle and concaves I have experienced many problems due abnormal power draw behavior of the electric motor in a primary gyratory crusher in iron ore crushing , especially when the

Learn More

how to change the cone crusher mantle?|News-CFTC

When the wear is serious, it needs to be replaced to restore the working performance of the equipment. The cone crusher mantle is one of the

Learn More

Crusher Operator - Livingston, Montana, USA Job Opening

Fisher Industries is a family of businesses that encompass all aspects of the aggregate production and heavy civil construction industries. Our unique, vertically-integrated business model allows us to handle small projects, large scale operations, and every tough job in between. Our goal is to provide reliable products and sustainable solutions for innovative global infrastructure. For

Learn More