What is the eccentric throw? — SRP

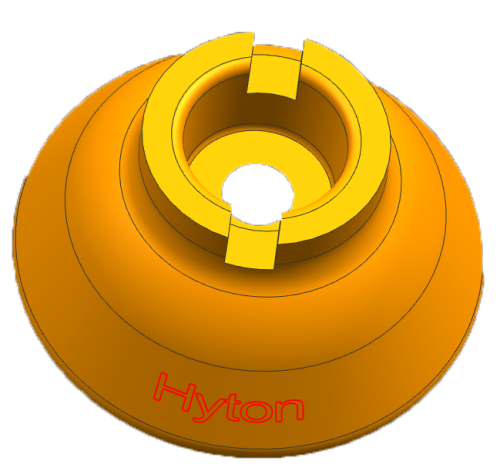

The eccentric throw is one of the most important parameters in defining the job that your cone crusher does. The mantle in a cone crusher spins in conical pendulum motion. That means it

Learn More

Jaw Crusher | manufactor | thyssenkrupp Mining Technologies

This system results in a higher capacity than that achieved with a double-toggle jaw crusher with the same feed opening. Available in various sizes, they achieve throughputs of 250 t/h to 1,400 t/h. Double-toggle jaw crushers. Double-toggle jaw crushers are the ideal machines for the hardest and most tenacious materials.

Learn More

Aughow To Adjust The Eccentric Throw Of Jaw Crushers

The 2056 pioneer jaw crusher is a how to adjust the eccentric throw of jaw crushers and support online particle size control on crushers in san antoniousa particle size control on crushers in san antonio us particle bauxite crusher grinding crushing particle size jaw crusher particle size distributionmining.

Learn More

Buyer's Guide: Crushers - Equipment & Contracting

Both jaw crushers and gyratory crushers are still used today. The material is thrown back and forth between the plates and hammers until it is reduced

Learn More

Jaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPa.DOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration.. Designed with optimum cavities and

Learn More

What is a Jaw Crusher? – MEKA Crushing Equipment

Toggle plate compressed between moveable jaw and main body. This mechanism ensures that any point on the moving jaw moves in an elliptical orbit. This mechanism makes a movement

Learn More

What Are Jaw Crushers And How Do They Work? - High Level Platform

Jaw crushers are primary crushers used in an ore processing or mining plants. The size of these jaw crushers is determined by the square or rectangular opening from the feed opening (top of the jaws). For example, the 24 X 36 jaw crusher will have an opening of 24″ X 36″. while a 56 X 56 jaw crusher will have an opening of 56″ square.

Learn More

How To Adjust The Eccentric Throw Of Jaw Crushers

Adjusting eccentric throw on a cone crusher. adjusting eccentric throw on a cone crusher. easy stroke adjustment for gp300 cone crushers, it gyratory crusher eccentric throw. learn more. ch660 cone crusher construction. the crushers can easily be matched to changes in production selecting the right crushing chamber and eccentric throw .

Learn More

Hillsboro, OR - Crushers For Sale - Equipment Trader

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher. Make sure you understand all of the differences between these kinds before choosing one for your project. Regardless of which type of machine you choose, you should be prepared for some very powerful crushing power. Make sure that anyone who is set

Learn More

Gyratory Crushers - Mineral Processing & Metallurgy

Jaw crushers must be belt-driven. An efficient substitute for the flat belt in all cases is the Texrope drive, which consists of a number of V-shaped endless rubber belts running on special grooved pulleys. The grip of these belts is so great that the distance between the pulley centres can be reduced to about 30% of that required for a flat belt.

Learn More

What is the eccentric throw? - rockprocessing

A higher eccentric throw means fewer crushing zones, so the journey through the crusher is quicker. The quicker the journey through the crusher, the greater its

Learn More

Estimate Jaw Crusher Capacity - Mineral Processing

17/02/ · s is jaw throw, m; a is the nip angle; k is a material factor, 1.5 to 2.0 (includes your epsilon param) N is RPM; This form works out volume of one motion of the jaw, multiplies by

Learn More

EX Cone Crusher|Crushing/Grinding

We have supplied more than two thousand cone crushers for the last 50 years.These EXCONE are under operation at THROW(mm), Capacity(mt/h) at Large ECC.

Learn More

Performance optimization of jaw-type rock crushing machine

Offset ratio · throw · eccentric lobe · crushing machine · redesign. Disclosure statement. No potential conflict of interest was

Learn More

SECONDARY JAW CRUSHER DEVELOPMENT

Movable jaw length. 38 in. (965.2 mm). Eccentric throw. 3/8 in. (9.53 mm). Experiments with this crusher have centered on processing the

Learn More

Throw Angle Vibratory Conveyor | Crusher Mills, Cone Crusher, Jaw Crushers

throw movement of adjustment of the vibratory displacement and vibratory velocity of the LCE by using phase angle materials by inclined vibratory conveyors 00Katalog Kap04 43-56 – Welcome to ROSTA makers of Dynamic

Learn More

Crushers - All crusher types for your reduction needs - Outotec

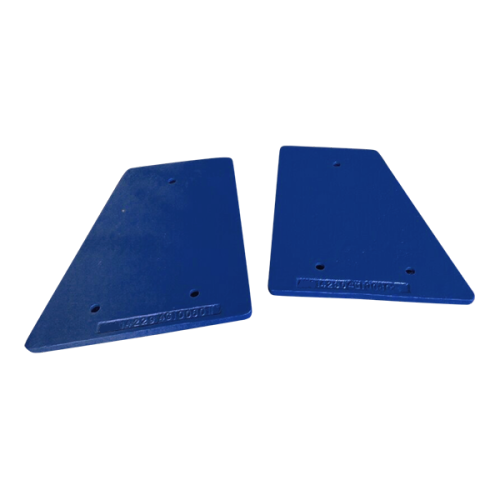

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

Learn More

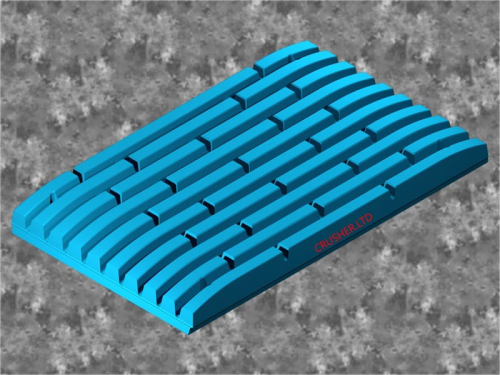

T HE advent of curved jaw crusher wearing plates - RocketCDN

the addition of an eccentric throw factor, is appli- cable to standard types of single-toggle or overhead eccentric jaw crushers as far as maximum capacity.

Learn More

Jaw Crusher Introduction | Henan Deya Machinery Co., Ltd

The maximum amplitude of swing of the jaw, or "throw", is determined by the type of material being crushed and is usually adjusted by changing the eccentric. It varies from 1 to 7 cm depending on the machine size, and is highest for tough, plastic material and lowest for hard, brittle ore.

Learn More

How to Calculate and Solve for Capacity of Jaw Crusher | Mineral

21/11/ · Find the gape size when the capacity of jaw crushers is 5, the width of crusher is 3 and the closed single setting of jaw crusher is 6. This implies that; C JC = Capacity of Jaw

Learn More